Project category

MACHINE VISION

The Challenge

Optical inspection.

A system able to realize several measures over mechanical turned items of different shapes is required. It’s also necessary to identify the exact measure of an axial hole diameter. The system has to automatically select the chosen elements, dividing scraps from those in tolerance.

The Solution

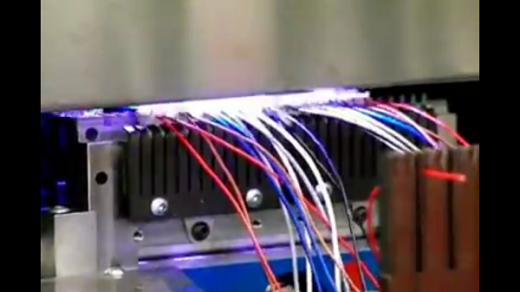

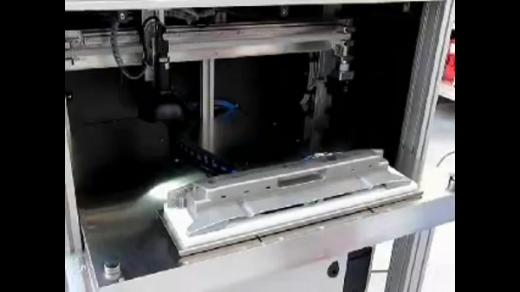

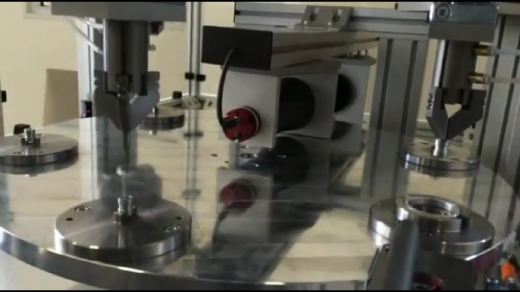

A vibrating feeder, rapidly customizable, supplies the oriented elements which are then collected and loaded on a rotating board. Two stations of the board contain a couple of camera/illuminator, both telecentric. Cameras allows to realize all measures concerning external profiles’ element. A third station manages a micrometer for internal measures which allows to scan the calibrated hole in all its length. Types of measure and tolerances can be programmed by a touch screen PC based software.

Installed in Italy.