Project category

AUTOMATED SOLUTION

The Challenge

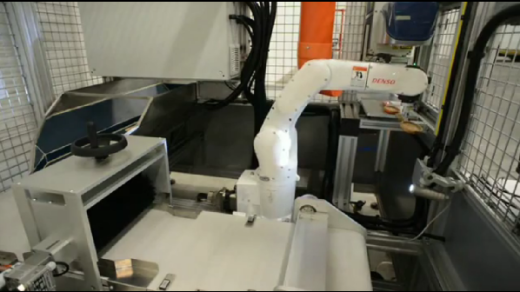

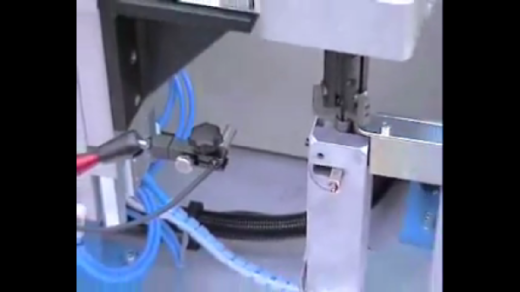

Flexible feeder.

The client required a system able to load sintered aluminum pieces with high levels of precision, in order to launch the calibration process. Every single piece going into the system has to be loaded, without any recirculation: as the pieces consist in gearshift mechanisms it’s necessary to guarantee a great care of the surface finishing.

The Solution

The system starts from a randomly made load of the pieces which are then distanced on a orientation belt (independently from the piece form). Over the belt, a vision system driven robot can flip pieces in order to put them in a right grip position. A second robot picks them up from the correct side, then orients them with a second high precision vision system so as to load these pieces with the highest accurancy. The system allows a production switch just by selecting the desired piece on the touch screen, without any mechanical setting.

Installed in Germany.